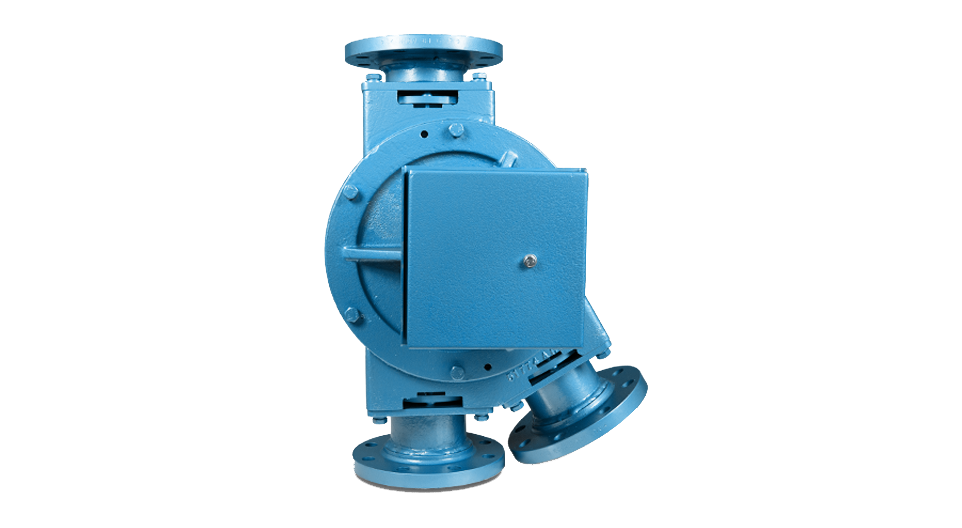

Used to re-route pellets or granules from one discharge point to another, the plug diverter is suitable for abrasive or high pressure applications, where leakage or cross contamination cannot be tolerated.

The valve consists of a rugged cast body which houses a cast plug between a pair of end covers. The material handled passes from one line through a tunnel within the plug to either of the two outlet lines. The material stream is diverted to the selected outlet by rotating the plug through 150°. Rotation is alternatively clockwise and counter-clockwise and is achieved by means of a double acting torque actuator.

To prevent cross contamination of product air to the chamber or dormant leg, sealing is achieved by means of a PTFE spring loaded gland arrangement accessible adjustable and replaceable externally.

The plug and body are precision machined using the latest CNC technology to ensure reliability and sealing efficiency. The valve has no dead-leg, smooth internals ensure no lodgement points, minimising turbulence and therefore ensuring line efficiency is kept to a maximum.

Pipe connections can be supplied as either plain pipe ends or flanged as required.

A choice of construction materials include Aluminium, Cast Iron and Stainless Steel in any combination, allowing the majority of applications to be catered for. Standard range size 50mm to 250mm diameter but we will extend this range should the need arise.

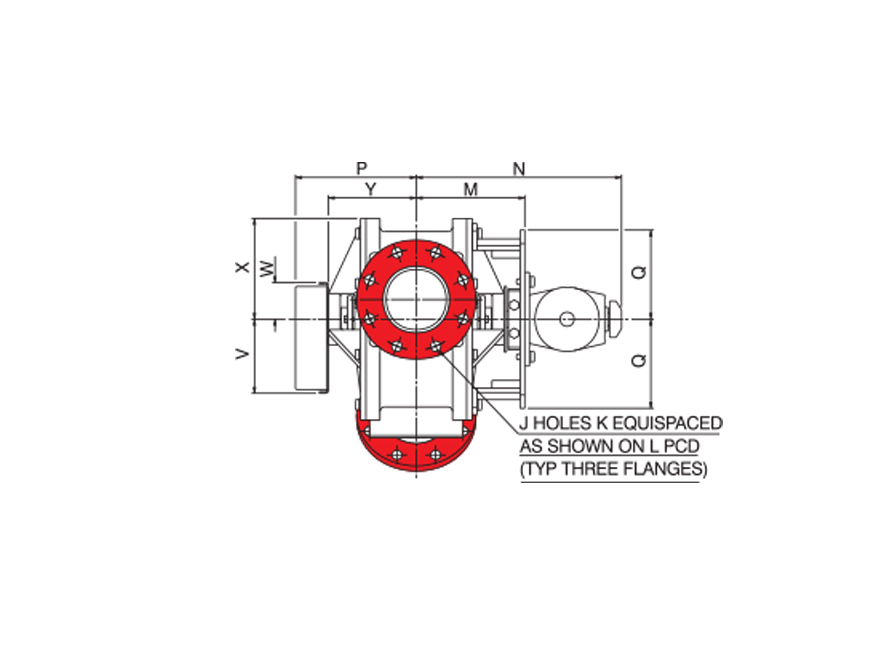

All dimensions are in mm unless otherwise stated

| SIZE | C | D | E | F | H | M | N | P | Q | U | V | W | X | Y |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 74 | 332 | 258 | 235 | 166 | 192 | 406 | 217 | 113 | 24.5 | 158 | 78 | 121 | 147 |

| 75 | 82 | 390 | 308 | 235 | 195 | 210 | 417 | 236 | 130 | 30.5 | 158 | 78 | 150 | 165 |

| 100 | 85 | 440 | 355 | 235 | 220 | 219 | 426 | 246 | 158 | 36 | 158 | 78 | 180 | 175 |

| 125 | 93 | 500 | 407 | 235 | 250 | 232 | 438 | 258 | 190 | 42 | 158 | 78 | 215 | 188 |

| 150 | 94 | 542 | 448 | 235 | 271 | 262 | 470 | 288 | 203 | 47.5 | 158 | 78 | 230 | 218 |

| 200 | 117 | 670 | 553 | 235 | 335 | 292 | 500 | 315 | 253 | 58.5 | 158 | 78 | 280 | 245 |

| 250 | 141 | 800 | 659 | 235 | 400 | 320 | 527 | 571 | 300 | 69.5 | 300 | 300 | 330 | 320 |