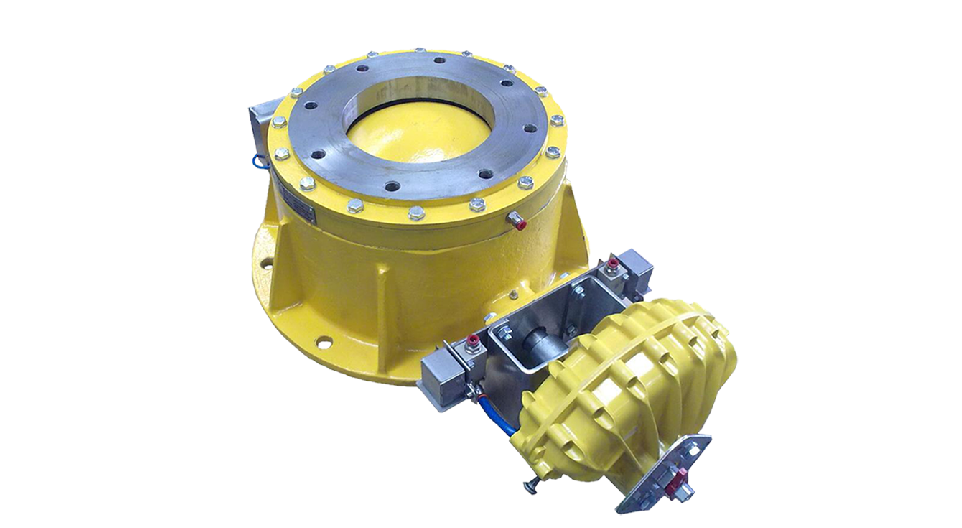

Roundhead valves are used in the bulk handling field as on/off controls for powder, pellets or granules falling under gravity from one discharge point to another. They are designed specifically to give a full bore opening in pressure applications and are particularly suited to handling abrasive products.

The valve consists of a cast body and inlet flanges with an internal cast dome and inflatable seal. The castings are CNC machined to ensure that the seal is properly seated and presses uniformly against the dome when inflated. The dome is clamped to side shafts which operate within impregnated bush bearings in the body with external lubrication points. Lip seal shaft seals protect the environment against product leakage and maintain any internal pressure.

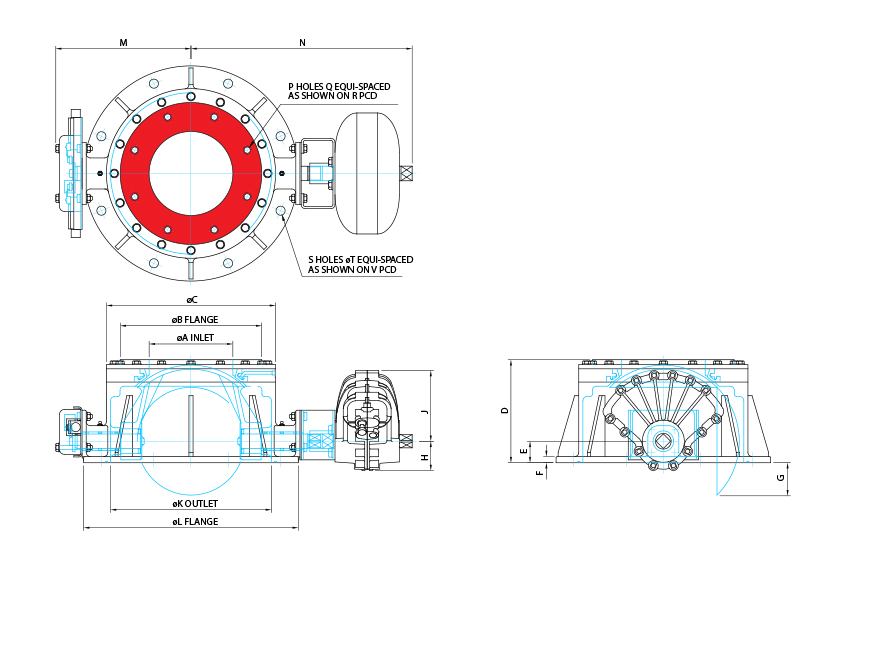

All dimensions are in mm unless otherwise stated

The valve consists of a cast body and inlet flanges with an internal cast dome and inflatable seal. The castings are CNC machined to ensure that the seal is properly seated and presses uniformly against the dome when inflated. The dome is clamped to side shafts which operate within impregnated bush bearings in the body with external lubrication points. Lip seal shaft seals protect the environment against product leakage and maintain any internal pressure.

| SIZE | A | B | C | D | E | F | G | H | J | K | L | M | N | P | Q | R | S | T | V |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 102 | 250 | 250 | 178 | 52 | 15 | 30 | 42 | 160 | 230 | 340 | 288 | 340 | 8 | M 16 x 16 DEEP 1 | 190 | 6 | 18 | 300 |

| 150 | 152 | 279 | 340 | 219 | 52 | 15 | 55 | 42 | 160 | 320 | 483 | 319 | 412 | 8 | M 20 x 20 DEEP | 242 | 8 | 22 | 390 |

| 200 | 203 | 343 | 410 | 249 | 52 | 15 | 80 | 71 | 171 | 390 | 520 | 338 | 538 | 8 | M 20 x 20 DEEP | 290 | 8 | 22 | 470 |

| 300 | 305 | 483 | 572 | 322 | 82 | 15 | 130 | 42 | 160 | 552 | 690 | 423 | 515 | 12 | M 22 x 22 DEEP | 432 | 12 | 26 | 630 |

| 400 | 406 | 597 | 750 | 436 | 100 | 35 | 138 | 90 | 235 | 720 | 920 | 521 | 631 | 16 | M 24 x 25 DEEP | 540 | 12 | 33 | 838 |